Piping System

Online Technical Topics

Online technical presentations on specific topics to support professionals in their daily work

Piping System

These online technical presentations have been developed to bring the rules for the Piping systems design mainly the Codes ASME B31.3, B31.4, B31.8, B16.5, B16.47, B16.34, API Std 600, API Spec. 6D and API RP 1111 between others that have been developed considering piping typically found in petroleum refineries; chemical, cryogenic plants; and related processing plants and terminals, pipeline transportation systems for liquids and gas transmission and distribution piping systems.

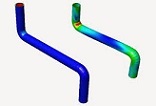

Following the paragraph 304.1.2 "Straight Pipe Under Internal Pressure for t<D/6", the internal pressure design thickness for straight pipe shall be not less than that calculated in accordance with either eq. (3a)

Following the paragraph 403.2 "Criteria for Pipe Wall Thickness and Allowances". The nominal wall thickness of straight sections of steel pipe shall b equal to or greater than tn determined in accordance with the following equation: tn ≥ t+A

Following paragraph 841.1.1 "Steel Pipe Design Formula for the design pressure for steel gas piping systems or the nominal wall thickness".

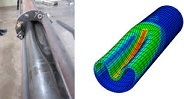

Following paragraph 304.1.3 "Straight Pipe Under External Pressure" to determine wall thickness and stiffening requirements for straight pipe under external pressure.

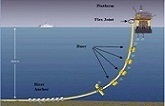

Wall Thickness Calculation of Straight Steel Pipes in Offshore Liquid Pipeline Systems by ASME B31.4

Following "Offshore Liquid Pipeline Systems" (Chapter IX), paragraph A403.2 "Criteria for Pipe Wall Thickness and Allowance".

Following "Offshore Gas Transmission" (Chapter VIII), paragraph A842.2.1 "Strengh Criteria During Operations".

Following the API RP 1111 "Design, Construction, Operation, and Maintenance of Offshore Hydrocarbon Pipelines (Limit State Design)".

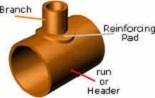

Following paragraph 304.3.3 "Reinforcement of Welded Branch Connections". Added reinforcement is required to meet the criteria in paras. 304.3.3(b) and (c) when it is not inherent in the components of the branch connection.

Piping Layout must be carried out with Process requirements, economy, orderliness, stress and supporting requirements in mind. Proper support selection should be the objective of all phases of design and construction.

Following ASME B16.5 and B16.47. These Standards covers pressure–temperature ratings, materials, dimensions, tolerances, marking, testing, and methods of designating openings for pipe flanges and flanged fittings.

Following the below standards:

a. Valves — Flanged, Threaded, and Welding End - ASME B16.34

b. Steel Gate Valves—Flanged and Butt-welding Ends, Bolted Bonnets - API Std 600

c. Specification for Pipeline and Piping Valves - API Spec. 6D